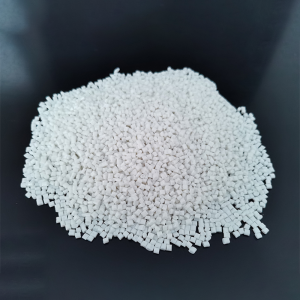

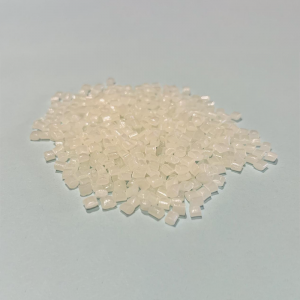

Super-bright (SBC) Polyester Chips

Product Introduction

Super-bright polyester chips are suitable for making the terylene filament, industrious filament,terylene staple fiber, PET film, injection mould and the other packing materials etc.

The brand of product is a special kind of super-bright chip with good color values, excellent diaphaneity, less impurity and constant viscosity. For applying the unique process recipe and production technology, the chips possess excellent processing property, high rate of the finish product, less broken fiber and less rate of blown film. So the chips are especially used to produce the lustrous fine denier filament and high-speed polyester film.

Techncal index

|

Ttem |

Unit |

Index |

Test method |

|

|

Intrinsic Viscosity |

dL/g |

0.650±0.012 |

GB/T 14190 |

|

|

Melting point |

°C |

>258 |

GB/T 14190 |

|

|

Color value |

L |

— |

>62 |

GB/T 14190 |

|

b |

— |

4±2 |

GB/T 14190 |

|

|

Carboxyl end group |

mmol/kg |

<30 |

GB/T 14190 |

|

|

DEG content |

wt% |

1.1±0.1 |

GB/T 14190 |

|

|

Water content |

wt% |

<0.4 |

GB/T 14190 |

|

|

Powder dust |

ppm |

<100 |

GB/T 14190 |

|

|

Agglomerate particle |

pc/mg |

<1.0 |

GB/T 14190 |

|

Specification

|

Specification: |

5011 |

|

Feature and performance: |

Favorable color value, favorable transparency, less impurity and stable viscosity. |

|

Applicability: |

Dacron long thread, industrial long thread, Dacron cut fiber, polyester thin film, injection moulding and other packing materials. |

|

Main raw material: |

PTA, MEG |