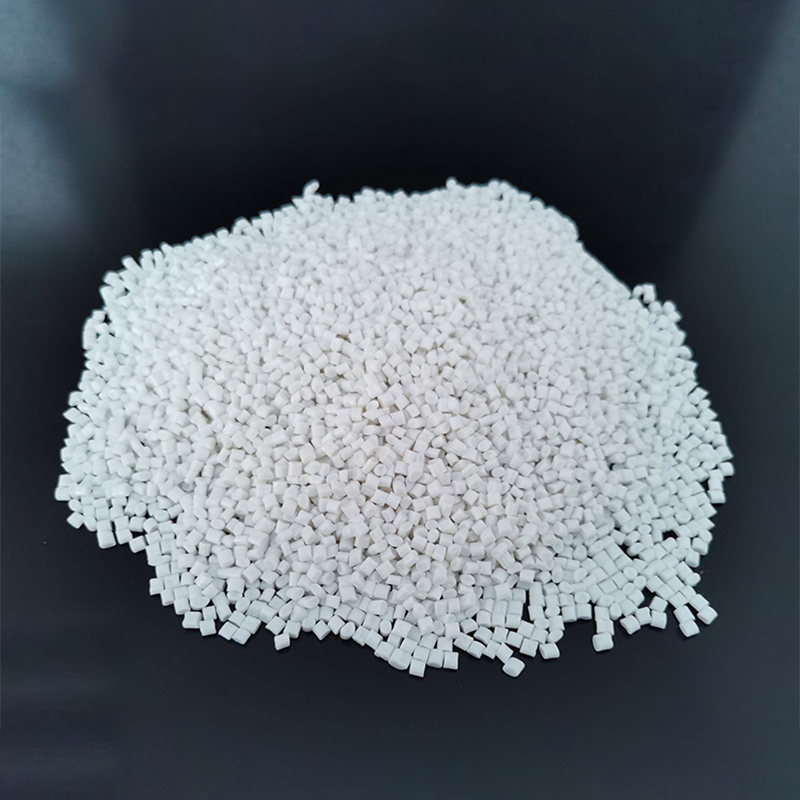

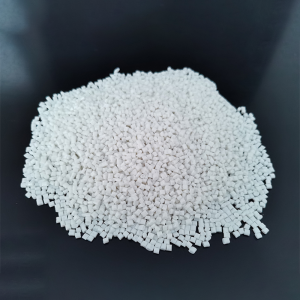

Full Dull (FD) Polyester Chips

Product Introduction

Full dull polyester chip are a differentiated product that has emerged in China in recent years, due to its high TiO2 content, it changes some characteristics of the melt, compared with semi dull polyester chips, making it higher in the selection of process and quality control in the production process. This paper mainly discusses the production of fully extinct varieties by masterbatch method from the perspective of process setting and production control. In the production process of Full dull polyester chip, the spinning temperature has a great influence on the operation of spinning and elasticization and the dyeing performance of the finished product; The masterbatch addition ratio and the cycle of components also affect the smooth progress of the spinning process; The choice of untwisting tension has a great influence on the hair condition of DTY. Therefore, this article focuses on the selection of the above processes. In terms of quality control of finished products, through the use of wire tensiometer, monitoring the tension fluctuation during wire strip processing, quality control can be carried out throughout the fiber process; Various factors affecting the finished unwinding performance and methods to improve the unwinding performance are also discussed. In this paper, we also compare the supramolecular structure of fibers with other polyester products to analyze the differences in characteristics between the two products.