PTA(Pure Terephthalic Acid)

Product production process

PTA is the lower end of petroleum. Petroleum undergoes a certain process to produce naphtha (also known as light gasoline), from which MX (mixed xylene) is extracted, and then PX (paraxylene) is extracted. PTA uses PX as raw material and acetic acid as solvent, and is oxidized by air under the action of a catalyst to generate crude terephthalic acid. Then the crude terephthalic acid is hydrorefined to remove impurities, and then crystallized, separated, dried and prepared refined terephthalic acid products, that is, PTA finished products.

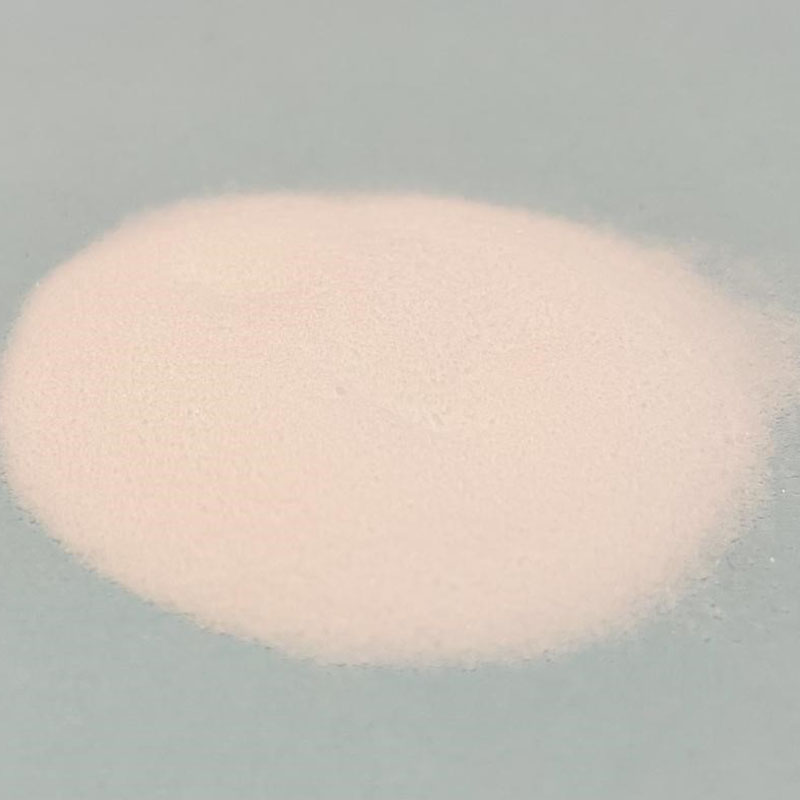

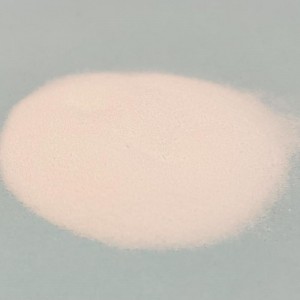

Product introduction

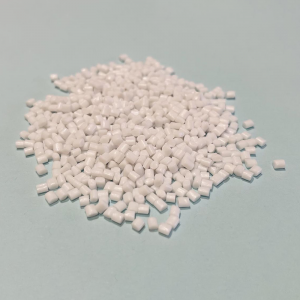

PTA is white crystal or powder at room temperature, low toxicity and flammable. Its ignition point is 384~421 °C, sublimation heat 98.4kJ/mol, combustion heat 3225.9kJ/mol, and density 1.55g/cm3. It's soluble in alkali solution, slightly soluble in hot ethanol, insoluble in water, ether, glacial acetic acid and chloroform.

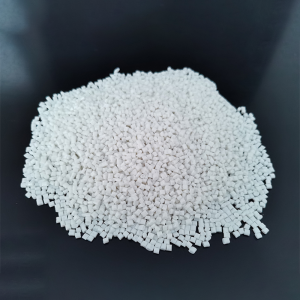

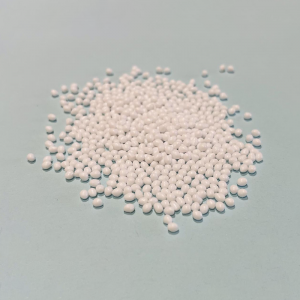

Product application

Important raw materials for the manufacture of polyester fibers, films, plastic products, insulating paints and plasticizers, and are also used as dye intermediates.

PTA is one of the important bulk organic raw materials, widely used in chemical fiber, light industry, electronics, construction and other aspects of the national economy.

The application of PTA is relatively concentrated, more than 90% of the world's PTA is used in the production of polyethylene terephthalate (referred to as polyester, PET). To produce 1 ton of PET, 0.85-0.86 tons of PTA and 0.33-0.34 tons of MEG (ethylene glycol) are required. Polyester includes fiber chips, polyester fibers, bottle chips and film chips. In China, 75% of PTA is used to produce polyester fiber; 20% is used in the production of bottle-grade PET resin, mainly used in the packaging of various beverages, especially carbonated beverages; 5% for film-grade polyester, mainly used in packaging materials, films and tapes. Therefore, the downstream products of PTA are mainly polyester fiber.