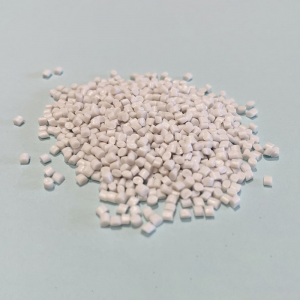

Fast Reheated CSD PET Resin

Product Introduction

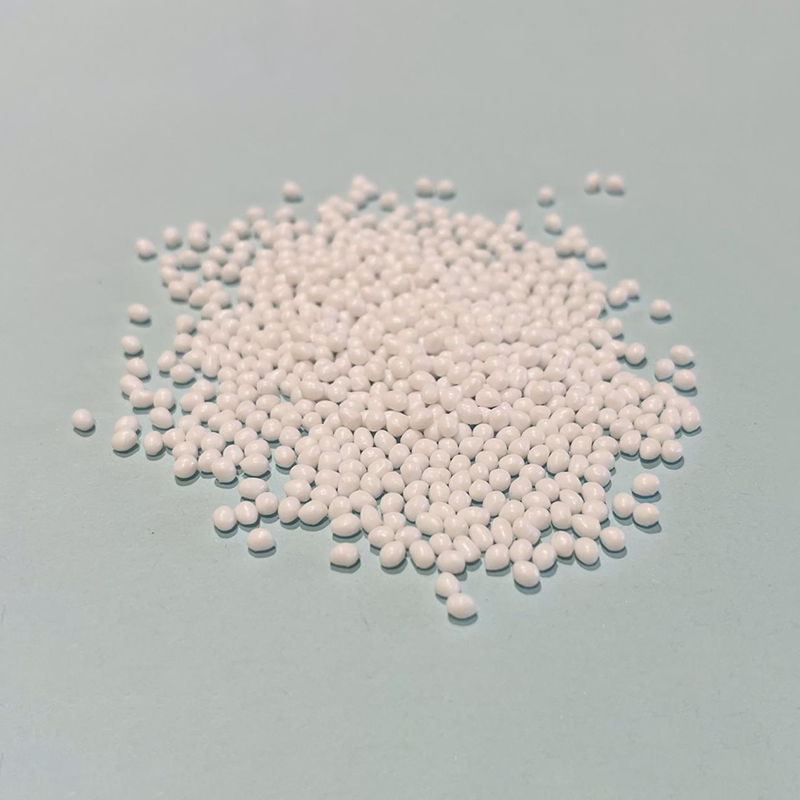

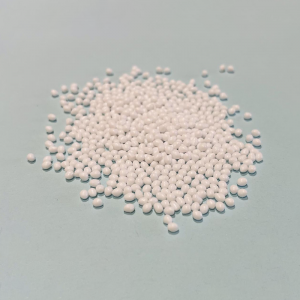

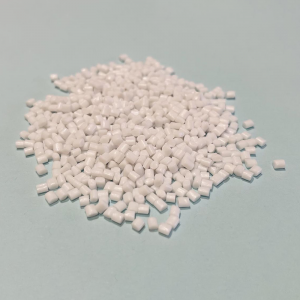

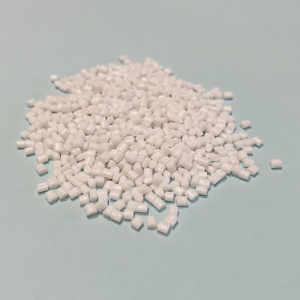

Fast Reheated CSD PET Resin, which are suitable for applicating the two step blowing process to make packing bottles for carbonated drinks and have been widely used by manufactures in South and North America, Europe and Coca-cola China.

During the production process, this kind of chips has the main characteristics of fast absorption of heat, lowering energy consumption, increasing blowing speed and output, and improving efficiency. Due to the unique process recipe and advanced production technology, this new product has excellent properties and leaves the main performance standards as basic Carbonated bottle grade chips unchanged. The color for this kind of chips is a little bit dull, but the end products are excellent in transparency.

Techncal Index

|

Ttem |

Unit |

Index |

Test method |

|

|

Intrinsic Viscosity (Foreign Trade) |

dL/g |

0.850±0.02 |

ASTM D4603 |

|

|

Content of acetaldehyde |

ppm |

≤1 |

Gas chromatography |

|

|

Color value |

L |

一 |

≥72 |

HunterLab |

|

b |

|

≤0 |

HunterLab |

|

|

Carboxyl end group |

mmol/kg |

≤30 |

Photometric titration |

|

|

Melting point |

℃ |

243±2 |

DSC |

|

|

Water content |

wt% |

≤0.2 |

Weight method |

|

|

Powder dust |

ppm |

≤100 |

Weight method |

|

|

Wt. of 100 chips |

g |

1.55±0.10 |

Weight method |

|

Typical Processing Conditions

Drying is necessary prior to the melt processing to prevent the resin from hydrolysis. Typical drying conditions are an air temperature of 165-185 ℃, 4-6 hours residence time, dew-point temperature below -40 ℃ .

Typical barrel temperature about 280-298 ℃ .