1.pet resin introduction

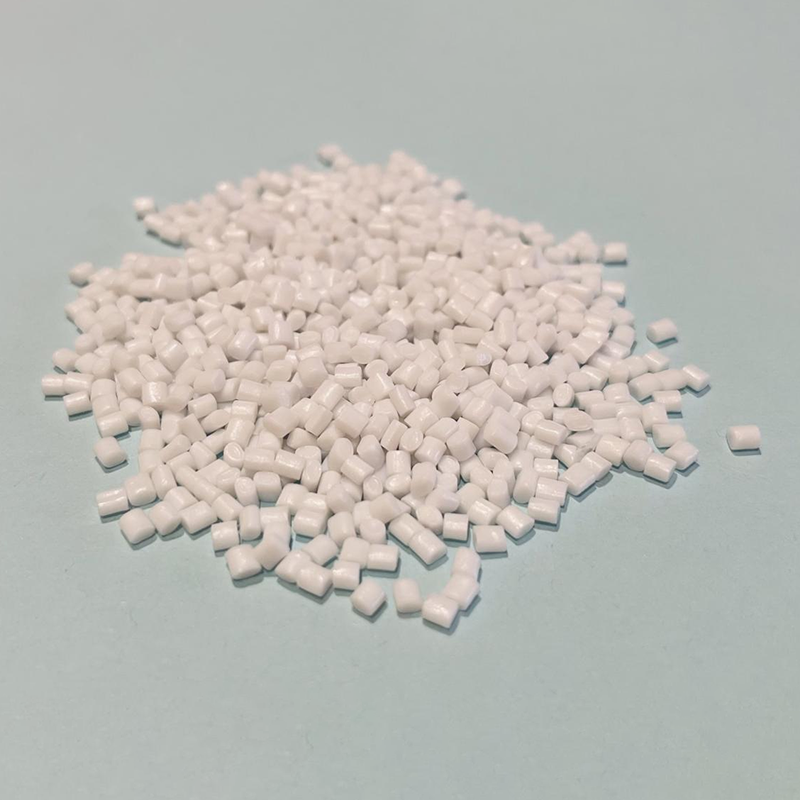

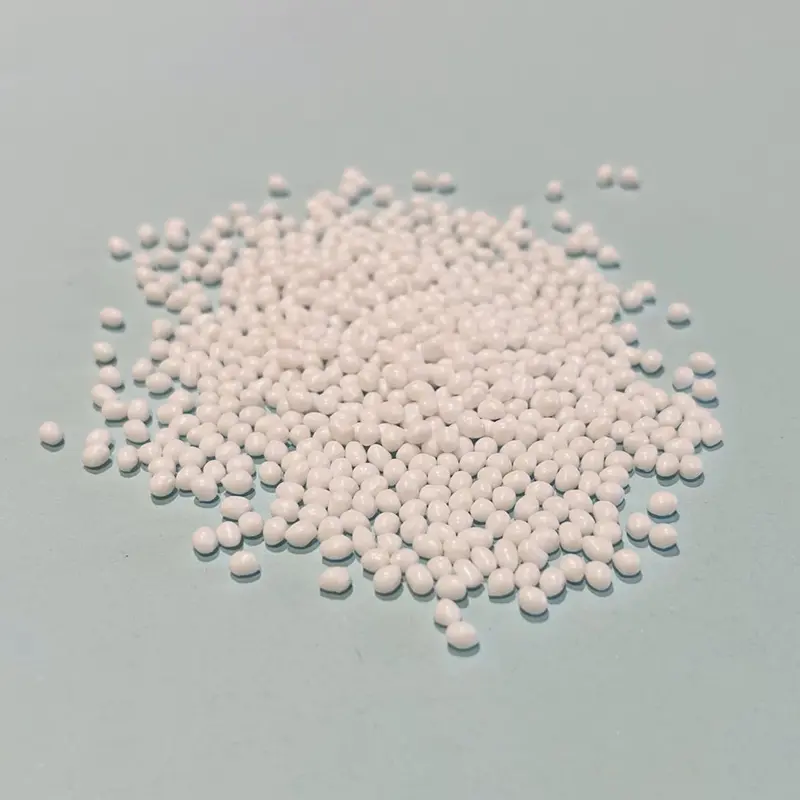

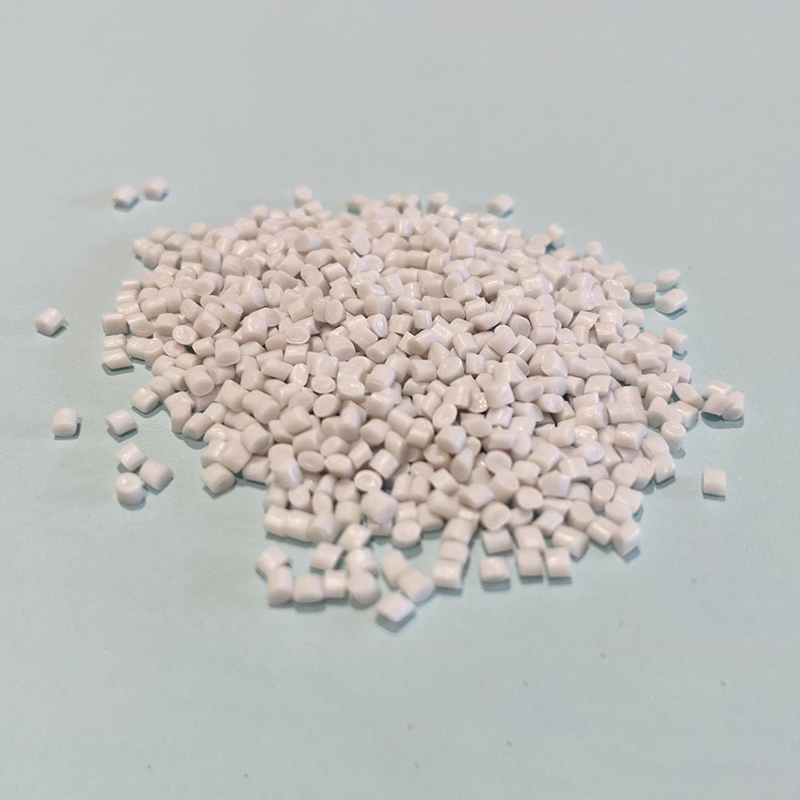

PET chemical name Polyethylene terephthalate, also known as polyester, chemical formula COC6H4COOCH2CH2O. Dihydroxyethyl terephthalate was prepared by transesterification of dimethyl terephthalate with ethylene glycol or esterification of terephthalate with ethylene glycol, and then polycondensation reaction. It is a crystalline saturated polyester, milky white or light yellow, highly crystalline polymer with smooth and glossy surface. It is a common resin in life and can be divided into APET, RPET and PETG.

PET is a milky white or light yellow, highly crystalline polymer with a smooth, shiny surface. It has excellent physical and mechanical properties in a wide temperature range, long-term use temperature up to 120℃, excellent electrical insulation, even at high temperature and high frequency, its electrical properties are still good, but poor corona resistance, creep resistance, fatigue resistance, friction resistance, dimensional stability are very good. PET has ester bond, decomposition will occur under the action of strong acid, strong alkali and water steam, resistance to organic solvents, good weather resistance.

2.resin properties

PET has good creep resistance, fatigue resistance, friction resistance and dimensional stability, small wear and high hardness, and has the largest toughness in thermoplastics: good electrical insulation performance, little influence by temperature, but poor corona resistance. Non-toxic, weather resistance, good stability against chemicals, low water absorption, resistance to weak acids and organic solvents, but not heat resistant water immersion, not alkali resistance.

PET resin has high glass transition temperature, slow crystallization rate, long molding cycle, long molding cycle, large molding shrinkage, poor dimensional stability, brittle crystallization molding, low heat resistance.

Through the improvement of nucleating agents and crystallizing agents and glass fiber reinforcement, PET has the following characteristics in addition to the properties of PBT.

1. Thermal deformation temperature and long-term use temperature are the highest in thermoplastic general engineering plastics.

2. Because of the high heat resistance, the enhanced PET is impregnated for 10S in the solder bath at 250 ° C, almost without deformation or discoloration, which is especially suitable for the preparation of electronic and electrical parts for solder welding.

3. The bending strength is 200MPa, the elastic modulus is 4000MPa, the creep resistance and fatigue are also very good, the surface hardness is high, and the mechanical properties are similar to thermosetting plastics.

4. Since the price of ethylene glycol used in the production of PET is almost half that of butanediol used in the production of PBT, PET resin and reinforced PET are the lowest price among engineering plastics and have a high cost performance.

To improve PET properties, PET can be alloyed with PC, elastomer, PBT, PS class, ABS, PA.

PET (enhanced PET) is mainly processed by injection molding, and other methods include extrusion, blow molding, coating and welding, sealing, machining, vacuum coating and other secondary processing methods. Dry thoroughly before forming.

Polyethylene terephthalate is prepared by transesterification of dimethyl terephthalate with ethylene glycol or esterification of terephthalate with ethylene glycol, and then polycondensation reaction. It is a crystalline saturated polyester, the average molecular weight (2-3)×104, the ratio of weight average to number average molecular weight is 1.5-1.8.

Glass transition temperature 80℃, Martin heat resistance 80℃, thermal deformation temperature 98℃(1.82MPa), decomposition temperature 353℃. It has excellent mechanical properties. High rigidity. High hardness, small water absorption, good dimensional stability. Good toughness, impact resistance, friction resistance, creep resistance. Good chemical resistance, soluble in cresol, concentrated sulfuric acid, nitrobenzene, trichloroacetic acid, chlorophenol, insoluble in methanol, ethanol, acetone, alkane. Operating temperature -100 ~ 120℃. Bending strength 148-310MPa

Water absorption 0.06%-0.129%

Impact strength 66.1-128J /m

Rockwell hardness M 90-95

Elongation 1.8%-2.7%

3. processing technology

PET processing can be injection molding, extrusion, blow molding, coating, bonding, machining, electroplating, vacuum gold plating, printing. The following mainly introduces two kinds.

1. Injection stage ① temperature setting: nozzle: 280~295℃, front 270~275℃, middle forging 265~275℃, after 250-270℃; Screw speed 50~100rpm, mold temperature 30~85℃, amorphous mold is 70℃, back pressure 5-15KG. ② Trial dehumidification dryer, material tube temperature 240~280℃, injection pressure 500~1400℃, injection molding temperature 260~280℃, drying temperature 120~140℃, take 2~5 hours.

2. In the film stage, the PET resin is sliced and pre-dried to prevent hydrolysis, and then the amorphous thick sheet is extruded in the extruder at 280 ° C through the T-mold, and the cooling drum or coolant is quenched to keep it in an amorphous form for tensile orientation. The thick sheet is then bidirectional stretched by the tenter to form a PET film.

Longitudinal stretching is to preheat the thick sheet to 86~87℃, and at this temperature, stretch about 3 times along the extension direction of the thick sheet plane, so that its orientation can improve the degree of crystallization to reach a higher temperature: the transverse preheating temperature of 98~100℃, the tensile temperature of 100~120℃, the tensile ratio of 2.5~4.0, and the thermal setting temperature of 230~240℃. The film after vertical and horizontal stretching also needs to be heat-shaped to eliminate the film deformation caused by the stretching and make a film with good thermal stability.

Post time: Sep-05-2023